Post-Processing Software

Transforming 3D scanner data for use in industry applications

Typically 3D scanners capture raw scan data and perform basic clean up for fast and simple operations (align, merge, and clean up). In order to process the data into useable form for its intended use—whether its for 3D visualization, reverse engineering, rapid prototyping, CNC machining, or quality inspection—post-processing software is required. Each Geomagic software package is specialized to perform specific industry applications.

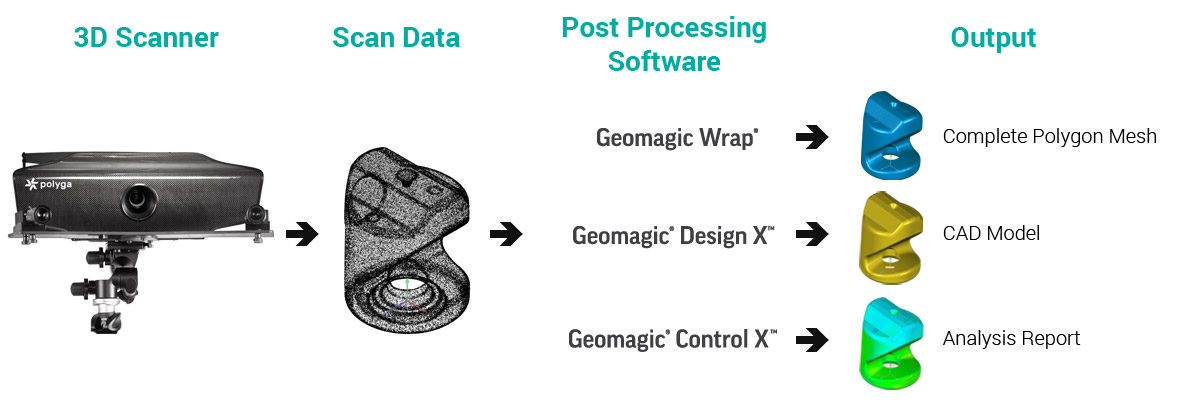

Workflow

From 3D Scanning to Post-Processing

Geomagic Software Comparison

Select the software depending on your downstream application

|

|

|

|

|---|---|---|---|

| Application | Surfacing, rendering, archiving, 3D printing | Reverse engineering | 3D inspection with reports |

| Ideal for | Advanced scan data editing functionalities | Advanced scan-to-design capabilities | Accurate 3D metrology and automation |

| Overview | Fast and easy creation of watertight 3D models from scan data. Delivers fast clean up of scan data, editing and repair of 3D data, and output to polygon, and surfaced models for use in a wide variety of applications. | 3D CAD modeling software that combines history-based CAD with 3D scan data to create feature-based, editable solid models compatible with existing CAD software. | Parts and 3D prints can be instantly and automatically inspected and compared with CAD models for conformance to tolerances. |

Geomagic Wrap

Transform 3D scan data into clean digital 3D models

Geomagic Wrap delivers the most easy-to-use, affordable, fast and accurate path from point clouds to 3D polygonal models. The software enables the transformation of point cloud and probe data to 3D polygon meshes for use in manufacturing, design, entertainment, archeology, and analysis.

Scan

Collect 3D scan data from physical objects to form the basis of the new 3D model using a 3D scanner or touch probe.

Process

Use Geomagic Wrap’s automated tools to clean scan data, create polygon data, or to remesh existing tessellated models.

Use

Export your 3D model to STL and OBJ file formats for immediate use of data in 3D printing or for use as reference data in CAD systems, and in analysis and rendering.

Geomagic Design X

Comprehensive and accurate 3D scan-to-CAD solution

Geomagic Design X creates manufacturing-ready CAD models directly from scan data. It works with every 3D scanner, and makes native, feature-based models for every major CAD application. The software’s redesign tools save a fraction of the time compared to reverse engineering using regular CAD software. Since Design X is built on a complete CAD kernel (Parasolid), it gives you the flexibility to make real CAD models the way you want.

Scan

Collect 3D scan data from physical parts to be used for measurement and comparison to reference data using a 3D scanner or touch probe.

Process

Extract design intent, build CAD model, and confirm quality with Accuracy Analyzer.

Use

Transfer to your CAD software with design history, save as neutral formats like IGES and STEP, or native file export for Solid Edge and AutoCAD.

Geomagic Control X

Reduce waste, eliminate production error, and deliver reliability

Geomagic Control X is the ultimate metrology software for delivering repeatable and reliable quality inspection process in any manufacturing workflow. Quickly conduct First Article inspections using the CAD-based dimensioning tools. Easily investigate quality issues that may appear across parts or over time. Native CAD importers including those containing model-based GD&T definitions are delivered standard at no extra cost. You get communication-ready information to share with stakeholders instantly at your fingertips.

Scanning

Using non-contact scanners (direct scanner integration and scanning automation), CMMs, probes, and walk up inspection tools, measurements can be quickly taken, analyzed and reported.

Inspection

Parts manufacturers use Geomagic Control X to verify the integrity of manufactured parts and to quickly identify issues that occur during manufacturing.

Report

Powerful reporting features in Geomagic Control X enable graphically-rich, communicative reports. Deliver customized reports to all stakeholders the way you want.

Request A Quote

Request Geomagic Software pricing information.

Contact Us