In manufacturing, there are deficiencies in the production process that can be improved with automation, whether it is increasing productivity or eliminating defective products coming down the assembly line. At Innovia3D, we bring together technologies, engineering expertise, processes, and people to develop automated solutions that encourage efficiency.

Automated Random Bin Picking

Challenge: Bin Picking is a Complex 3D Challenge

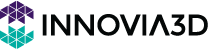

Components are randomly arranged in bins that need to be placed on a conveyor belt in precise orientation and position on an in-line production line for assembly. Parts need to be picked from the bin at a steady flow. Robots can aid in bin picking but it is a complex challenge. Parts are stacked randomly in a bin overlapping each other and need to be grasped by key points by robots. Parts have to be picked without collision.

Solution: 3D Vision for Robotic Guidance

3D vision solves these issues. Using 3D smart sensor mounted on an advanced universal robots unit, this system allows robots to collect objects randomly arranged within a container or being moved along a conveyor belt. The system is precise, easy to configure, and consistent over time. 3D sensor guided robotics are transforming the manufacturing landscape by enabling robust part flow and eliminating errors.

Automated Inspection

Challenge: Manual Inspection Susceptible to Error

A typical manufacturing line produces hundreds of parts per hour. Speed is critical in catching defects in a part immediately. Manual inspection using employees to watch the production line for defects is not effective. While looking or correcting defects, others are overlooked. This method requires constant attention and is taxing on employee productivity. An oversight can result in hundreds of defective parts resulting in wastage of time, labor and materials.

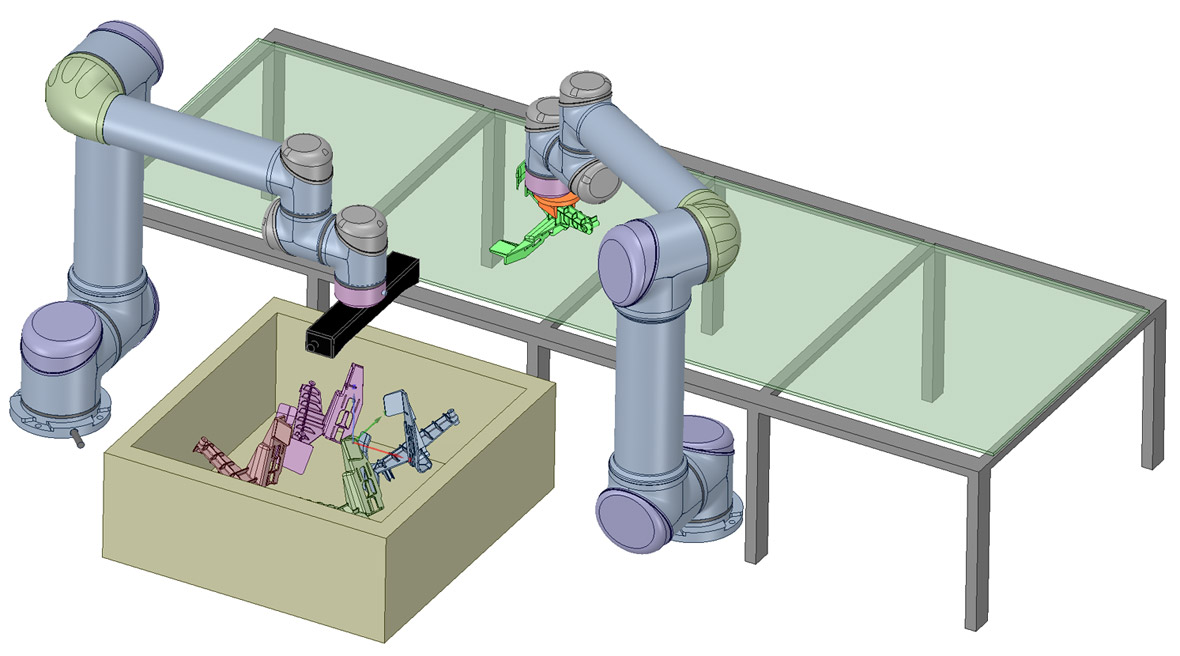

Solution: Automated Inspection using 3D Scanners

Our team has solved just this type of challenge for a leading manufacturer of building materials for the construction and remodeling industries. A 3D scanner mounted on a production line constantly takes critical measurements of every part produced. First, each part face is scanned in 3D and a visual image is produced. The 3D image is then analyzed for defects in depth, height and density. Using our skills in knowledge management, a dashboard was created to display all this data live in real time. This dashboard highlights critical alerts while displaying standard information about each part produced.

Industrial automation has been a key to productivity boost for factories. Combining automation with 3D scanners provides the next level with feedback for machines to make intelligent choices.

Custom Solutions

Every company has their own unique set of challenges. We can work with you to create customized solutions for automating demanding 3D measurement applications.

Ask our specialist

Contact our 3D scanning and inspection specialist to discuss how we can help you on your project.

Contact Us